How to Choose the Right Self Aligning Ball Bearing for Your Application

In the world of mechanical engineering, selecting the appropriate components is crucial for the efficiency and longevity of machinery. One such essential component is the Self-Aligning Ball Bearing, which plays a significant role in various applications ranging from automotive machinery to industrial equipment. As industry expert Dr. Emily Thompson emphasizes, "Choosing the right Self-Aligning Ball Bearing can make all the difference in ensuring optimal performance and reducing operational downtime."

When considering the right Self-Aligning Ball Bearing for your specific needs, several factors come into play, including load requirements, speed, and operational conditions. This bearing type is designed to accommodate misalignment and is particularly beneficial in applications where shaft alignment may be an issue. By understanding your application's unique demands, you can make a more informed decision that leverages the advantages of Self-Aligning Ball Bearings to their fullest potential.

In this guide, we will explore the top ten considerations for selecting the right Self-Aligning Ball Bearing, helping you navigate through the plethora of options available in the market. With insights gleaned from industry experts and practical tips, this comprehensive overview aims to equip you with the knowledge necessary to make a confident and informed choice, ultimately enhancing the performance of your machinery.

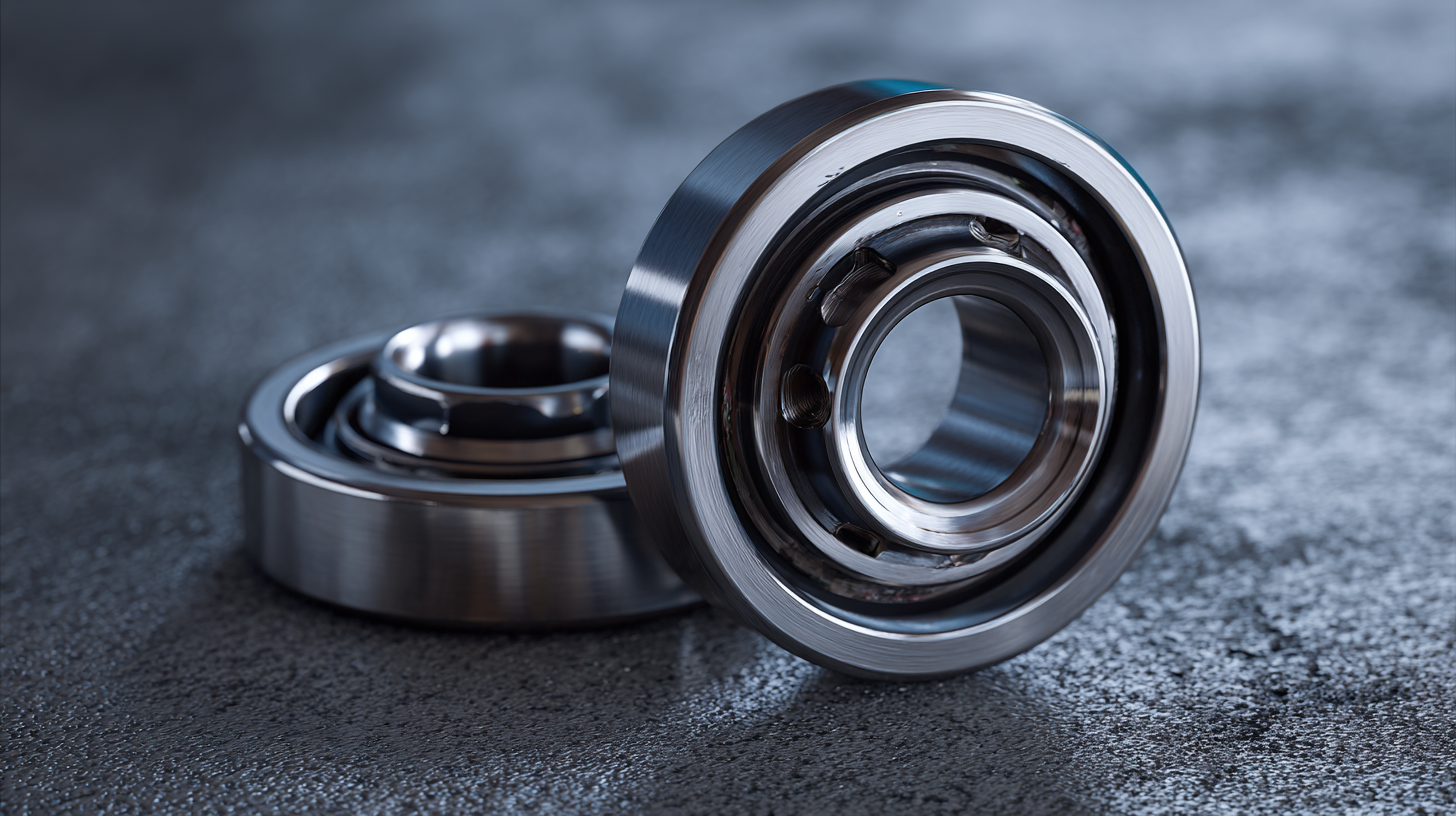

Understanding the Basics of Self Aligning Ball Bearings

Self-aligning ball bearings are a crucial component in various mechanical systems, offering unique advantages over traditional bearing types. They consist of two rows of balls and a common spherical raceway in the outer ring, allowing for self-alignment. This design accommodates misalignment and shaft deflection, making them particularly suitable for applications in industries such as automotive, manufacturing, and agricultural machinery. According to a report by MarketsandMarkets, the self-aligning ball bearing market is expected to grow at a CAGR of 5.2% from 2023 to 2028, reflecting their increasing adoption in modern engineering applications.

Understanding the operational principles of self-aligning ball bearings is vital for selecting the right type for specific applications. These bearings can handle radial loads as well as moderate axial loads, which is advantageous in systems where shaft misalignment may occur. Additionally, data from the International Journal of Engineering Research indicates that self-aligning bearings can significantly reduce maintenance costs due to their inherent ability to tolerate misalignment, thereby extending service life. Selecting the appropriate material and design configuration, based on load conditions and environmental factors, can further optimize performance and reliability in any given setup.

How to Choose the Right Self Aligning Ball Bearing for Your Application

| Bearing Type | Inner Diameter (mm) | Outer Diameter (mm) | Width (mm) | Load Rating (kN) | Speed Rating (RPM) | Applications |

|---|---|---|---|---|---|---|

| Self Aligning Ball Bearing | 20 | 42 | 12 | 10.5 | 4800 | Agricultural Machinery |

| Self Aligning Ball Bearing | 25 | 52 | 15 | 15.8 | 4500 | Textile Machines |

| Self Aligning Ball Bearing | 30 | 62 | 16 | 20.5 | 4200 | Pumps and Compressors |

| Self Aligning Ball Bearing | 35 | 72 | 20 | 32.5 | 3900 | Electric Motors |

| Self Aligning Ball Bearing | 40 | 80 | 22 | 45.0 | 3500 | Construction Equipment |

Identifying Key Application Requirements and Constraints

When selecting a self-aligning ball bearing for your specific application, it is crucial to start by identifying the key requirements that your application demands. Consider factors such as the load capacity, speed, and operating environment. Assess the types of loads the bearing will encounter—static or dynamic—as well as their magnitude and direction. Furthermore, evaluating the rotational speed requirements will ensure that the bearing operates effectively within its design parameters while maintaining durability.

In addition to load and speed, factors such as temperature, moisture, and contamination levels are essential in determining the right bearing. For instance, if your application is in a high-temperature environment, selecting a bearing with materials that can withstand elevated temperatures is critical. Similarly, in applications exposed to moisture or dust, bearings with adequate sealing features or special coatings should be prioritized. By carefully considering these application-specific constraints, you can make a well-informed choice that enhances performance and longevity.

In addition to load and speed, factors such as temperature, moisture, and contamination levels are essential in determining the right bearing. For instance, if your application is in a high-temperature environment, selecting a bearing with materials that can withstand elevated temperatures is critical. Similarly, in applications exposed to moisture or dust, bearings with adequate sealing features or special coatings should be prioritized. By carefully considering these application-specific constraints, you can make a well-informed choice that enhances performance and longevity.

Evaluating Material and Design Specifications for Bearings

When choosing the right self-aligning ball bearing for your application, evaluating material and design specifications is crucial. The material used in bearing manufacturing significantly impacts its performance, durability, and resistance to wear.

Common materials include chrome steel, stainless steel, and ceramic. Chrome steel offers excellent strength and hardness, while stainless steel provides enhanced corrosion resistance, making it ideal for applications in humid or chemically aggressive environments.

On the other hand, ceramic bearings are favored in applications that demand high speeds and low friction.

The design specifications of the bearings also play a vital role in their suitability for specific tasks. Key factors to consider include the bearing size, load capacity, and operating temperature range.

Self-aligning ball bearings are designed with sphered outer surfaces, allowing for misalignment between the shaft and housing. Ensure that the selected bearing can accommodate the expected load while operating efficiently within its designated temperature limits.

Additionally, features such as sealing mechanisms and lubrication types should also be assessed, as they can dramatically influence the longevity and performance of the bearing in real-world conditions.

Comparing Load Capacities and Environmental Considerations

When selecting the right self-aligning ball bearing for your application, understanding load capacities and environmental considerations is crucial. Load capacity varies significantly based on the design and materials used in the bearing. For instance, choosing bearings with higher load capacities can improve the performance and durability of machinery, but one must balance this with the potential environmental impacts. Increased load capacity might lead to heavier materials and higher energy consumption, which can exacerbate greenhouse gas emissions—a pressing concern highlighted by recent environmental statistics.

**Tip:** Always evaluate the load requirements of your application meticulously. Consider initial and long-term impacts on energy consumption and carbon footprint.

Moreover, environmental considerations, such as the use of sustainable materials and energy-efficient designs, play an increasingly vital role in modern engineering practices. Companies are now more frequently integrating green investment principles into their designs, thus enhancing the sustainability of bearing production and usage.

**Tip:** Research and select bearings designed with eco-friendly materials and production processes to minimize environmental impact while optimizing load performance. Assess the overall life cycle of the bearing, from manufacturing to disposal, to ensure your choice aligns with both efficiency and sustainability goals.

Load Capacities of Self Aligning Ball Bearings

Selecting the Right Supplier for Quality Assurance and Support

When selecting self-aligning ball bearings, quality assurance and supplier support play critical roles in ensuring the success of your application. A reputable supplier not only provides high-quality products but also offers extensive technical support and guidance throughout the selection process. When evaluating potential suppliers, consider their experience in the industry, customer testimonials, and the range of products they offer. Engaging with suppliers who prioritize customer satisfaction and have a strong support system will significantly enhance your purchasing experience.

When selecting self-aligning ball bearings, quality assurance and supplier support play critical roles in ensuring the success of your application. A reputable supplier not only provides high-quality products but also offers extensive technical support and guidance throughout the selection process. When evaluating potential suppliers, consider their experience in the industry, customer testimonials, and the range of products they offer. Engaging with suppliers who prioritize customer satisfaction and have a strong support system will significantly enhance your purchasing experience.

Tips: To choose the right supplier, ask about their quality control processes. A good supplier should have certifications that demonstrate their commitment to quality standards. Additionally, inquire about their delivery practices; a reliable supplier should be able to meet your timeline without compromising product integrity.

Another essential aspect is the level of after-sales service provided by the supplier. A knowledgeable support team can assist with installation and troubleshooting, ensuring that you can quickly resolve any issues that arise during the bearing's lifecycle. Building a relationship with a supplier who is responsive and resourceful can lead to better outcomes for your projects.

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat